Part #1 -- Fiberglass Basics

![]()

![]()

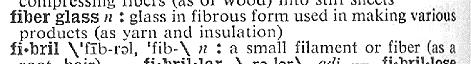

As the definition explains it is small fibers of glass mixed together with other ingredients. When you work with this stuff you should wear protective clothing, eye protection, and some sort of mask or respirator especially when sanding. If you didn't wear protective clothing you sure will kick yourself in the butt when your itching and scratching two days later. The glass particles will stick in your skin and they don't have any plans to leave any time soon.

Parts are made from a mold in which there is a tooling gel applied to the mold which hardens in to a very hard surface. The tooling gel also makes removal of the finished piece from the mold possible. After the gel has hardened, fiberglass and resin are layered on top of the gel to to form the piece. There is allot of heat generated from the curing of the resin so it is necessary to have several layers of fiberglass and resin to dissipate the heat section by section. Because of the time required to assemble these several layers, it may take a few weeks to finish one piece from a mold.

Anyone who has tried to make their own mold and get just one good piece out of it can tell ya "Damn that's allot of work !" I personally have never tried making anything with fiberglass, but have heard many stories, so I stayed away from it. For a more detailed description of how parts are made go to Marks Custom Kits he has done a very good job on describing how parts are made.

Once out of the mold you will see the tooling gel again, this will be the surface that you will need to finish. When you get something out of the mold it will not be perfect pretty much anywhere. You will need to fill, sand, fill again, and sand some more it is a long process. The more time you take and the better you planned for the project, the better the project will look when you are done. You shouldn't expect to finish off a dash earlier then 2-3 weeks of work. ( unless you have nothing to do all day long and have allot of free time. )

One more note: When you are attaching accessories or mounting the dash with hardware you need to be aware that all the fasteners should be snug not seriously torqued down. If you over tighten a fastener on fiberglass the fiberglass will crack, guaranteed !! Be careful.

Tools I would recommend using for this project are :

-- A Dremel type tool with a cutting blade.

-- A jig saw with a Plexiglas cutting blade.

-- The correct size hole saw for your gauges.

-- A hand held belt sander with a rough belt & a smooth belt

-- A drill press for the hole saws.

-- A hot glue gun.

-- Pop rivets and pop rivet tool.

-- A hand held variable speed drill.

-- Body filler / forming tools.

-- A palm vibrating sander

-- Tons of sand paper.

-- An assortment of Phillips type screw drivers.

-- An assortment of Phillips type sheet metal / machine screws, nuts, and washers.

© Property of Knight Technology http://knighttech.tripod.com